EAGLE PROVIDES THE WORLD'S MOST RELIABLE

AND ACCURATE AMMO

QUALITY

Our manufacturing partner Hughes Precision has the world’s fastest and most accurate ammunition inspection system available. It is a high speed comprehensive inspection system that detects all critical defects according to MIL-STD-636 for small caliber, and MIL-STD-651 for medium caliber ammunition and components.

AMMUNITION TESTING STANDARDS:

Primer Machines

Loading Machines

AMMUNITION SEALING

Hughes Precision provide predictable ammunition for unpredictable environments.

Ammunition is not traditionally sealed against water, and the casing is not sufficient protection in inclement weather or marine environments.

Our sealants ensure reliable ammunition performance and result in improved ballistic accuracy.

Ammunition can be freely moved through and below water environments.

FEATURES & BENEFITS

Hughes Precision has a unique ammunition sealing process to ensure that ammunition is waterproofed and can be taken into and under water environments without losing functionality.

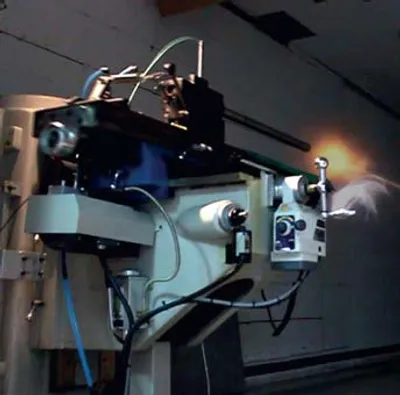

We have custom built machines. These machines are outfitted with a bowl feeder or robotic arms to enhance the loading process and can easily seal up to 300 rounds per minute.

TESTING FACILITIES